WARNING

It draws the operator's attention to situations which can jeopardize people's safety.

BoxerAgri welcomes you to the growing family of new product owners. This implement has been designed with care and built by skilled workers using quality materials. Proper assembly, maintenance, and safe operating practices will help you get years of satisfactory use from the machine.

Application

The Flail Mowers are designed for Category 1 - three point hitch or Quick-Hitch System mounting. These Fixed Bar Flail Mowers are ideal for ripping, leveling, finish grading, and backfilling applications at feedlots, outdoor arenas, building sites, and maintenance operations on farm and ranch lanes or roadways.

Using This Manual

Terminology

“Right” or “Left” as used in this manual is determined by facing the direction the machine will operate while in use unless otherwise stated.

Definitions

Note: A special point of information that the operator must be aware of before continuing.

Important: A special point of information related to its preceding topic. The intention is that this information should

be read and noted before continuing.

Owner Assistance

The Warranty Registration card should be filled out by the dealer at the time of purchase. This information is necessary to provide you with quality customer service. If customer service or repair parts are required contact a dealer. A dealer has trained personnel, repair parts and equipment needed to service the machine.

The parts on your machine have been specially designed and should only be replaced with genuine parts.

Serial Number Plate

For prompt service always use the serial number and model number when ordering parts from your dealer. Be sure to include your serial and model numbers in correspondence also.

Thoroughly read and understand the instructions given in this manual before operation. Refer to the “Safety Decal”, read all instructions noted on them.

Do not allow anyone to operate this equipment who has not fully read and comprehended this manual and who has not been properly trained in the safe operation of the equipment.

Look For The Safety Alert Symbol

The SAFETY ALERT SYMBOL indicates there is a potential hazard to personal safety involved and extra safety precaution must be taken. When you see this symbol, be alert and carefully read the message that follows it. In addition to design and configuration of equipment, hazard control and accident prevention are dependent upon the awareness, concern, prudence and proper training of personnel involved in the operation, transport, maintenance and storage of equipment.

This booklet contains three "safety graphic symbols" which highlight the relevant danger levels or important information:

|

WARNING It draws the operator's attention to situations which can jeopardize people's safety. |

|

CAUTION It draws the attention to situations which jeopardize the machine efficiency but not people's safety. |

|

IMPORTANT It highlights general information which does not endanger people's safety or the efficiency of the parts. |

For your protection

Thoroughly read and understand the “Symbols” section, read all instructions noted on them.

Shutdown and storage

Use safety lights and devices

Transport machinery safely

|

IMPORTANT Do not tow a load that is more than double the weight of tractor. |

Keep riders off machinery

Practice safe maintenance

Prepare for emergencies

Wear protective equipment

Avoid high pressure fluids hazard

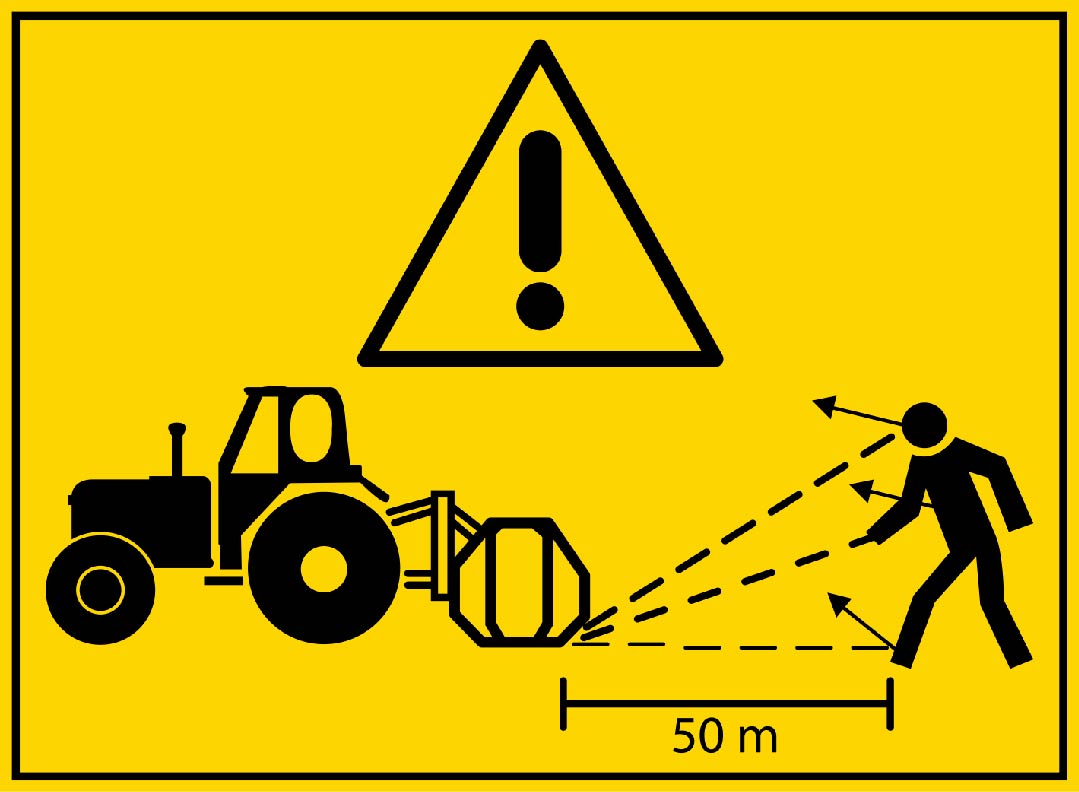

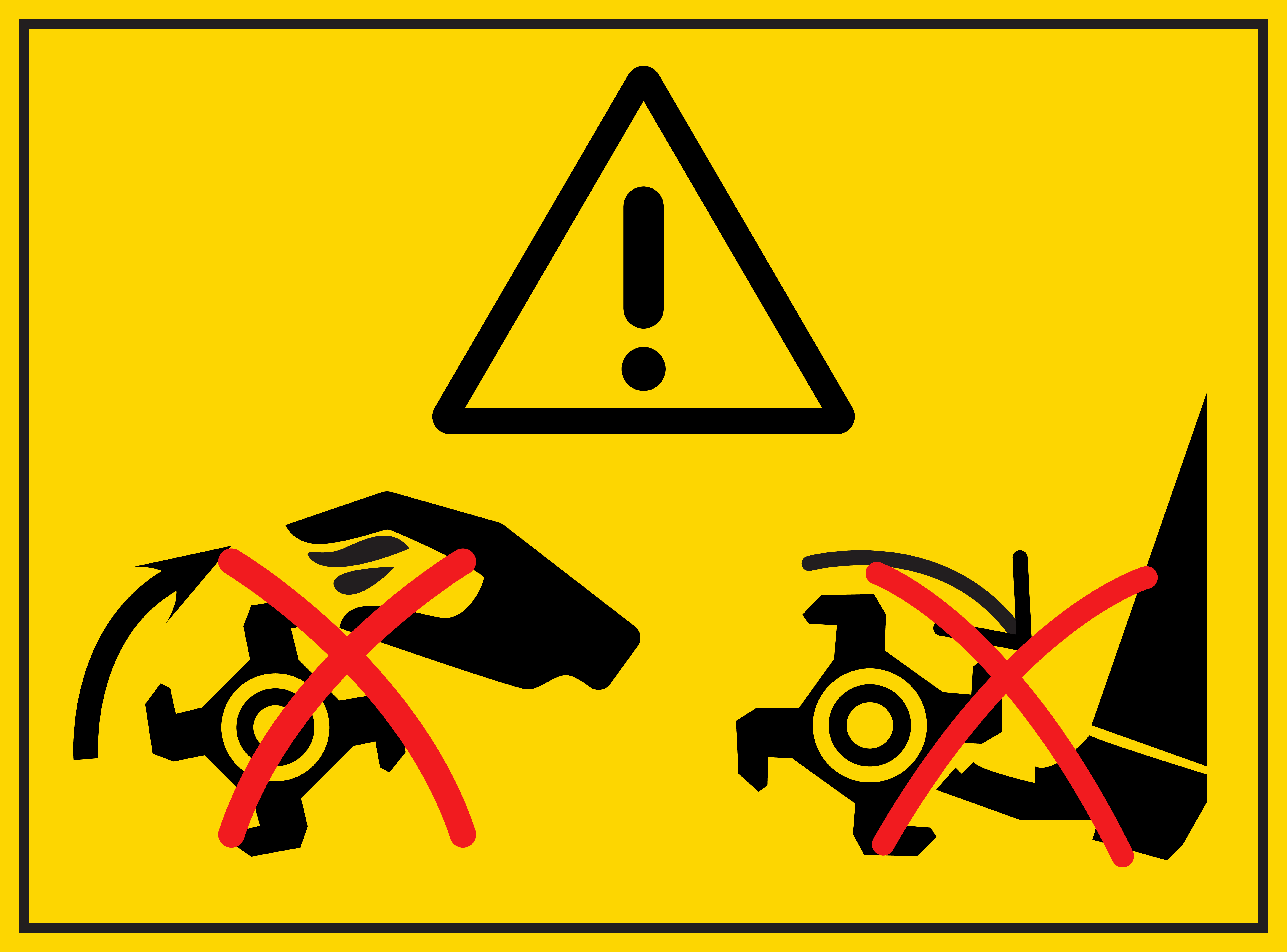

Your Flail Mower comes equipped with all safety labels in place. They were designed to help you safely operate your implement. Read and follow their directions.

To install new labels:

|

|

|

|

|

Tractor Requirements

This mower is designed with a 3-Point category I hitch. Tractor horse power rating should not exceed 80 PTO horse power.

Assembly

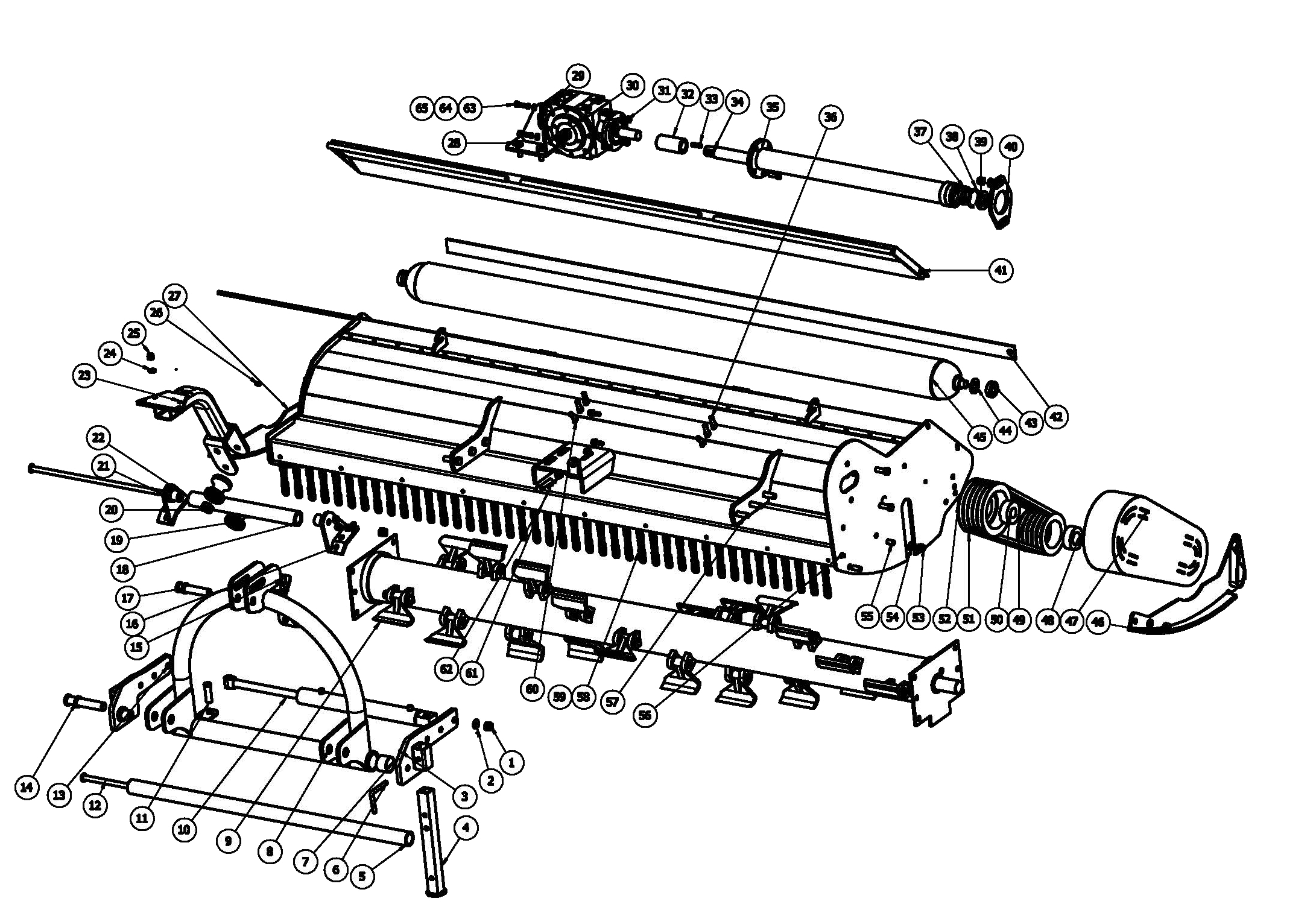

Refer to the parts illustration.

Tractor Hook-Up

Driveline Installation

|

CAUTION Tractor PTO shield and all mower guards must be in place at all times during operation! |

|

Model |

||||||

|

KDK 240 |

240 |

540 |

75 - 120 |

CAT. II |

650 |

22 |

|

KDK 300 |

300 |

540 |

100 -150 |

CAT. II |

1200 |

30 |

Transporting

NOTE: Always disengage PTO before raising mower to transport position.

|

CAUTION When traveling on public roads, whether at night or during the day, use accessory lights and devices for adequate warning to operators of other vehicles. Comply with all Federal, State, and local laws. |

Mowing Instructions

Operating Instructions

Proper servicing and adjustments are the key to the long life of any machine. With careful and systematic inspection of the mower, costly maintenance, time and repair can be avoided.

Before beginning to mow, the following inspection should be performed:

Leveling the Mower

NOTE: Tractor and mower should be on level ground.

Leveling can be adjusted at the tractor’s 3-point arms and center link.

Cutting Height Adjustment

3-Point Hitch Adjustments

The 3-point hitch system on this mower has been designed for front to back flotation when mowing on uneven terrain. Adjust tractor’s top center link to place the upper hitch pin vertically above or slightly behind the lower hitch pins. The mower should be run with the back 15 degrees lower than the front. The hitch can also be adjusted from side to side by turning the adjustment handle. Turn handle until you have achieved your desired location.

|

CAUTION Engage parking brake, shut off tractor, remove key and disengage PTO before making any height adjustments! |

Belt Tension

|

CAUTION Belt drive system under spring tension; use care to avoid bodily harm! |

The Belt tension should be checked after the first 20 hours of use. And then every 40 hours of use.

|

CAUTION Excessive tension on the belt may lead to premature failure of belt and drive components. Excessive tension on the belt may also lead to a safety hazard to the operator or bystanders. |

Maintenance

Proper servicing and adjustment is the key to the long life of any farm implement. With careful and systematic inspection, you can avoid costly maintenance, time and repair.

|

CAUTION For safety reasons, each maintenance operation must be performed with tractor PTO disengaged, mower lowered completely to ground and tractor engine shut off with ignition key removed. After using the mower for several hours, check all bolts to be sure they are tight and check drive belt tension. Replace any worn, damaged or illegible safety decals by obtaining new decals from dealer. |

Knife Replacement

|

IMPORTANT Make sure that the knife is the same length as the others on the mower. This will keep the rotor rotation balanced. |

V-Belt Installation

|

CAUTION Belt drive system under spring tension; use care to avoid bodily harm! |

Storage

At the end of the working season or when the mower will not be used for a long period, it is good practice to clean off any dirt or grease that may have accumulated on the mower and any of moving parts.

Lubrication

|

|

||

|

Driveline Shaft U-Joints |

|

Multi-purpose Grease |

|

Roller Bearing (Both Ends) |

||

|

Cutter Rotor Bearing (Both Ends) |

||

|

Gearbox |

Check oil level in gearbox by removing the plug located on the right hand side. Oil should be level with bottom of plug hole. Add oil if necessary by removing top fill plug and side plug. Add oil until it flows from side plug hole. Do not overfill! |

SAE 90W Gear Lube |

|

Driveline Profiles |

|

Multi-purpose Grease |

|

IMPORTANT Mower should be level when checking oil in gearbox! |

|

CAUTION Do not try to clean rear discharge area when mower is running. Bodily harm may occur! |

|

Problem |

Solution |

|

Belt slipping |

Unplug and clean mower deck. |

|

Remove belt guard shields and clean sheaves. |

|

|

Replace belt. |

|

|

Patches of uncut grass |

Mow at full throttle (540 PTO rpm), check PTO speed and tractor engine. |

|

Shift transmission to a lower gear. |

|

|

Tighten belts. |

|

|

Replace missing knives. |

|

|

Excessive vibration |

Replace knives. |

|

Replace drive belt. |

|

|

Replace pulleys or align. |

|

|

Remove belt guard shields & clean debris from belt area & sheaves. |

|

|

Gearbox noisy |

Check lubricant level. |

|

Knives scalping grass |

Raise cutting height by adjusting roller. |

|

Change mowing pattern. |

|

|

Reduce speed turns |

|

|

Uneven cut |

Shift to a lower gear. |

|

Level mower. |

|

|

Replace missing knives. |

|

|

Tractor loaded down by mower |

Mow at full throttle (540 PTO rpm). |

|

Shift to a lower gear. |

|

|

Clean mower. |

|

No. |

Part No. |

Description |

Quantity |

|

1 |

GB/T 889.1 |

Locking nut M16 |

30 |

|

2 |

GB/T 97.1 |

Plain washer 16 |

9 |

|

3 |

KDK240-012 |

Hang connecting weldment (R) |

1 |

|

4 |

KDK240-025 |

Support leg weldment |

2 |

|

5 |

KDK240-65 |

Guide rail axle |

1 |

|

6 |

|

Right angle pin |

2 |

|

7 |

|

Self-lubricating bearing |

|

|

8 |

|

Hanging weldment |

1 |

|

9 |

BCR140.102 |

Blade |

22 |

|

10 |

KDK240-296 |

Oil cylinder |

1 |

|

No. |

Part No. |

Description |

Quantity |

|

11 |

|

Cylinder pin shaft |

2 |

|

12 |

KDK200-67 |

Screw shaft weldment |

1 |

|

13 |

KDK240-013 |

Connection weldment |

1 |

|

14 |

KDK240-103 |

Down hanqing pin |

2 |

|

15 |

GB/T 5783 |

Hex bolt M12*45 |

4 |

|

16 |

KDK240-032-01 |

Upper guide connected symmetric weldment |

1 |

|

17 |

KDK240-104 |

Upper hanging pin |

1 |

|

18 |

KDL240-66 |

Guide rail axle 2 |

1 |

|

19 |

KDK240-62 |

Connecting sleeve |

2 |

|

20 |

|

Roller bearing |

4 |

|

No. |

Part No. |

Description |

Quantity |

|

21 |

KDK200-68 |

Screw shaft weldment |

1 |

|

22 |

KDK240-032 |

Upper guide connected weldment |

1 |

|

23 |

KDK240-033 |

Hana connecting weldment |

1 |

|

24 |

GB/T 97.1 |

Plain washer |

18 |

|

25 |

GB/T 889.1 |

Locking nut M14 |

18 |

|

26 |

GB/T 1152 |

Oil cup M8*1 |

1 |

|

27 |

KDK240-015 |

Plate weldment |

1 |

|

28 |

KDK20.016 |

Gear box assembly plate parts |

1 |

|

29 |

KDK240-214 |

Gear box assembly seat |

1 |

|

30 |

EF175-023 |

Gear box assembly |

1 |

|

No. |

Part No. |

Description |

Quantity |

|

31 |

GB 93-87 |

Spring washer 12 |

4 |

|

32 |

|

Connecting sleeve |

1 |

|

33 |

GB/T 1096 |

Key A 1 0 x 8 x 40 |

1 |

|

34 |

KDK240-113 |

Transmission shaft |

1 |

|

35 |

KDK200-018 |

Shaft sleeve weldment |

1 |

|

36 |

KDK240-010 |

Cover weldment |

1 |

|

37 |

GB/T 276-94 |

Deep groove ball bearing 6007 |

1 |

|

38 |

GB 893.1-86 |

Circlip 62 |

1 |

|

39 |

|

Oil seal |

1 |

|

40 |

KDK240-214 |

Gear box assembly plate parts |

1 |

|

No. |

Part No. |

Description |

Quantity |

|

41 |

KDK240-011 |

Fender weldment |

1 |

|

42 |

|

Scraper |

1 |

|

43 |

GB/T 276-94 |

Deep groove ball bearing 6205 |

2 |

|

44 |

|

Adjusting washer |

2 |

|

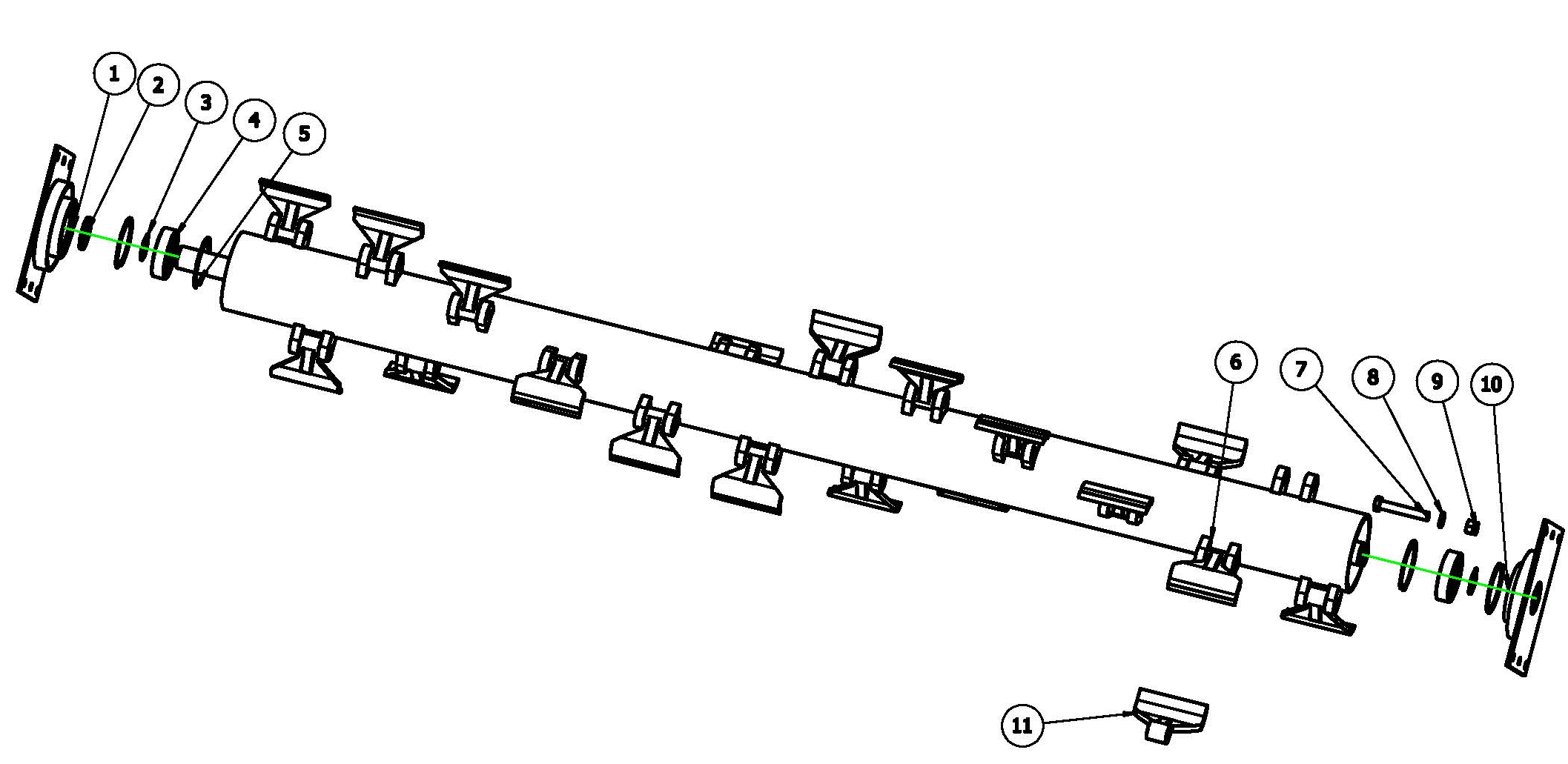

No. |

Part No. |

Description |

Quantity |

|

1 |

KDK200. 019-250 |

Bearing seat (R) |

1 |

|

2 |

|

Oil seal |

1 |

|

3 |

GB 894.11-86-45 |

Circlip 45 |

2 |

|

4 |

GB/T 276-94 |

Deep groove ball bearing 6309 |

2 |

|

5 |

GB 893.11-86-100 |

Circlip 100 |

2 |

|

6 |

KDK.240-013 |

Blade axle weldment |

1 |

|

7 |

GB/T 5782 |

Bolt M16*100 |

1 |

|

8 |

GB/T 97.1 |

Plain washer 16 |

1 |

|

9 |

GB/T 889.1 |

Nut M16 |

1 |

|

10 |

KDK200-020 |

Bearing seat (L) |

1 |

|

11 |

BCR140.102 |

Blade |

22 |